Collector feedback on the Alpha design led to many changes to the Brightvision bus. All these modifications were rolled into one new release for 2002. It was called “Omega”.

In short, the collectors loved the Alpha but wanted a version of the bus that was not only more accurate in its design representation, but more refined in finish. Even though the Alpha bus finish resembled the 30+ originals known to exist from 1968, collectors were after that “dead mint” “blister pack fresh” look!

Changes in casting method, tool design, plating process and paint systems came together to create the Omega. The end result was stunning visually, and collectors hailed the new Omega! Since the Omega was so desirable, a limited “trade-in” window in time was opened up for Alpha owners. Believe it or not, Alpha owners were invited to upgrade their Alphas for the new Omega at no cost, no questions asked! Many collectors took up the offer, while others held onto their Alphas believing that their bus would become even more collectable! Both collecting camps were correct! The folks that took advantage of the trade-in got a great looking Omega, and the folks that kept their Alpha have a real piece of die-cast history!

Here’s a detailed list of all the changes that went into the Omega

- General Design

- Die Cast Body

- Sunroof shortened into a more square shape from the rectangle on the Alpha

- Large “X” pattern removed from the roof

- Inner roof contour line moved closer to roof’s edge, both front & rear

- Side air-intake vents enhanced with more detail

- Front and rear side-markers given more definition

- Sliding door handle depression shortened from more of a crescent shape

- Interior – Text Base Omega only

- Steering wheel turned right-side up – Alpha and Omega Blank-Base cars were upside down

- Two support posts removed from underside of interior, visible through rear wheel wells and rear suspension holes in base. Alpha and Omega Blank-Base cars have 5 total support posts rather than 3 on the Omega Text-Base cars.

- Finish

- Plating process – added initial copper strike, then bright zinc plate

- Paint system moved to an automotive urethane enamel from acrylic lacquer on Alpha – NOTE: Alpha design received new automotive paint system in 2002 with release of Omega

- Process & Material

- Die-cast process moved to “Hot Chamber” technology to assist in rendering a smooth “hardware finish” on the body

- Raw material for casting moved to ZAMAC 5 from ZAMAC 4

- Die Cast Body

The end result looked longer and more sleek due to the revised sunroof and roofline. The many other small detail improvements came together to bring more accuracy and visual excitement. The new paint system just “knocked the ball out of the park” as they say! If you’re in the hunt for an Omega, they are well worth the chase!

Here is a side by side comparison between the Alpha roofline and the Omega. Of all the design changes on the Omega, the roofline had the largest visual impact. Note the difference in the shape of the sunroof. The Omega is almost square, and the Alpha is rectangular. Notice the “X” shape on the Alpha roof that is not visible on the Omega. Finally, notice the inner roof contour line. Notice how the Omega has a much smaller gap between the line and the front edge of the roof. This is also true of the rear. These changes made the roof appear longer and more sleek.

Alpha on left, Omega on right.

Side air-intake vents – Alpha on left, Omega on right

Rear Sidemarkers – Alpha on left, Omega on right

Sliding door handle depression – Alpha on left, Omega on right

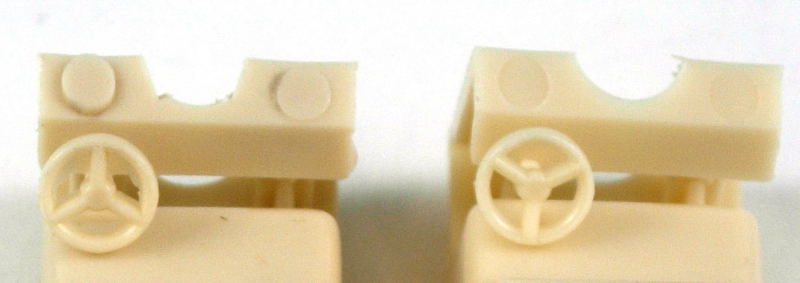

Steering wheel – Alpha on left, Omega on right

Interior support posts – Alpha on left, Omega on right

You can actually see the posts on the original Alpha interior through the base holes.

See below.

Red Alpha on left, Yellow Omega on right